Cementos Tudela Veguín has a central laboratory (Elías Masaveu Research Center) from where it develops all its lines of research, to then be applied in the industrial processes once they have been tested in the laboratory.

Cementos Tudela Veguín has a central laboratory (Elías Masaveu Research Center) from where it develops all its lines of research, to then be applied in the industrial processes once they have been tested in the laboratory.

Furthermore, continuous work is carried at these laboratories belonging to Corporación Masaveu in order to obtain new products.

The development of a new range of mortars with lime as their exclusive binder is being carried out. This type of mortar is used for restoring historical buildings in such a way that the material used is as similar as possible to the mortar with which the buildings were once constructed. This means hydraulic lime must be used, for it to set both in air and under the effect of water. What is formed chemically at a macromolecular level is a hydrate compound and not a carbonate compound, which happens with aerated lime.

The advantage of compounds formed by hydration is that they provide greater and faster resistance than those with a carbonate reaction, this being a basic point in the rhythm of present works.

This type of binder must be associated with sand in such a way it can be applied with certain ease, in the case of being used for rendering walls. Furthermore, chemical additives must be added to modify its water retaining capacity and also for the occluded air to protect its structure when facing freeze/thaw cycles, while also lightening and smoothing its texture, allowing for its application with a projection machine for rendering which, in this manner, will improve the execution times.

The amount of hexavalent chromium present in the cements used or manufactured in Spain is regulated following the legal requirements established by Directive 2003/53/CE, transposed to our regulations via Order PRE/1954/2004, of 22nd June.

Once the disadvantages of the additives traditionally used in Europe for hexavalent chromium reduction and the technical limitations of the few alternative additives present in the market were known, the laboratories of Tudela Veguín started developing a good Cr(VI) reducing product, which also eliminates the limitations and disadvantages of the additives already in existence.

Patent protection has been requested for this product, both at national and European level, with the file being in the final resolution stage at present.

The redox Cr(VI)/Cr(III) system has characteristics that are oxidising and very dependent on the pH of the means in which the reaction takes place. For this reason and given that cement leaching water is very alkaline, redox systems with reducing power under these specific conditions must be found.

CrO4 2- + 4H2O + 3e- ↔ Cr(OH)3 + 5OH-

In connection with the above, the great difficulty for reducing chromium (VI) in alkaline pH and the scarcity of reducing agents working effectively under these conditions should be highlighted.

The Technical Construction Code (CTE) is a mandatory document that includes the basic quality requirements with which buildings must comply. The CTE establishes these requirements for each requisite considered as being basic, such as energy savings and thermal insulation. The Basic Document describes the insulation/conductivity requirements of the different materials intervening in any construction. This point presents the opportunity of introducing innovative mortars, lighter than those usually used in construction. The use of this mortar improves the insulation properties, contributing in an essential manner towards energy savings.

There are many ways of lightening the materials in terms of the on-site implementation required, it being common to do so with expanded clay aggregates as this is more cost-effective. In this way, mortar mass is made lighter as these aggregates contain air microcells resulting from the high temperature expansion process through which they were generated. This ensures a lower thermal conductivity coefficient, translating into lower wall transmittance, as long as the bricks used are also compliant with the CTE requirements.

This binder is born as a response to the European and worldwide trend towards developing more ecologically-friendly binders by means of reducing emissions and a greater sustainability index, as its main component is blast furnace slag, a steel manufacturing by-product. When this slag is cooled suddenly, then subjected to a milling process and activated afterwards, it reaches similar properties to those of cement with regard to setting and hardening, with the advantage of a retraction which is hardly unnoticeable.

One of its possible applications is the use in pedestrian paths being carried out at several points throughout the Spanish geography, may they be fluvial, coastal or agricultural. The solution often applied due to its speed is asphalting, with the resulting negative visual impact caused in certain environments. A finish similar to that of earth which blends in with the surroundings is achieved with this binder.

It is also an innovative and environmentally friendly material for several reasons:

- It is based on steel manufacturing by-products.

- There are no CO2 emissions in its manufacture.

- It avoids the use of bituminous materials.

- It reduces the visual impact of the path executed, as a finish in the colour of the aggregate chosen is obtained without the need for pigments.

- It avoids the use of gravel in agricultural tracks, in this way eliminating the formation of dust which is very harmful to crops.

Due to its chemical composition, it is a highly DURABLE product as it is resistant to the attack of sulphides, often present in water flows or gypsum areas.

Its composition based on blast furnace slag translates into the DEVELOPMENT of RESISTANCES beyond 28 days.

On top of this, its RETRACTION is practically nonexistent, therefore eliminating the problem of cracks and gaps appearing, through which aggressive external agents could penetrate.

On the other hand, its low heat of hydration and long SETTING TIME make it very convenient regarding transport from the plant and its laying and compacting tasks, without the need for retarders.

Apart from the lines of research described, Tudela Veguín is also working on other lines which are not as developed as the ones already stated:

- Emission reduction and control.

- Innovation in sustainable quarry management.

- More sustainable cement production, minimising the use of natural resources.

- Energy efficiency improvement in the production process.

- The application of nanotechnologies to create concrete with new features.

- The logistical optimisation of the product and the raw materials.

- The development of products or solutions for eco-efficient construction (buildings and public works).

- A safe bet on the design and aesthetics of the final products.

This R&D work has become clear in both projects that are to be started up thanks to this Competitiveness Plan:

- The inclusion of a blast furnace slag mill in Aboño implies the use of this refuse as a Raw Material for the process, meaning its sustainable use. Also, adding this slag to clinker provides an added benefit which is the improved resistance of cement in aggressive environments such as marine ones.

- The adaptation of the fuel supply installations to the main intake of the clinker furnace of La Robla, in order to use organic waste which is not hazardous in small grain sizes (mainly made up by plastic with different cardboard, wood and textile ratios) as alternative fuels to oil, equally reduces the amount of waste dumped in the tip, as they are valued in compliance with the strict environmental air and waste incineration quality standards, while complying with the European waste regulations currently in force which forbid dumping in the tip any waste flow which could have any kind of alternative use. Also ahead of its time is the compliance with the new European framework regulations on waste management, published in 2008 and about to be transposed to the national legal ordinances, taking a step forward in the philosophy of using, as far as possible, the resources contained in waste to avoid this from being squandered in tips. The inclusion of waste valuation processes to obtain energy reduces the dependency on fossil fuels and, similarly, their consumption.

This generic terms designates all the physical forms in which calcium oxide, also denominated quicklime, may appear and forming part of the so-called aerated limes which are those which harden slowly through contact with air and, in general, without hydraulic properties.

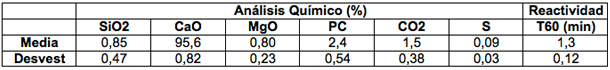

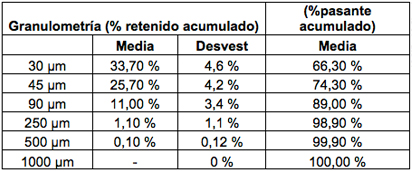

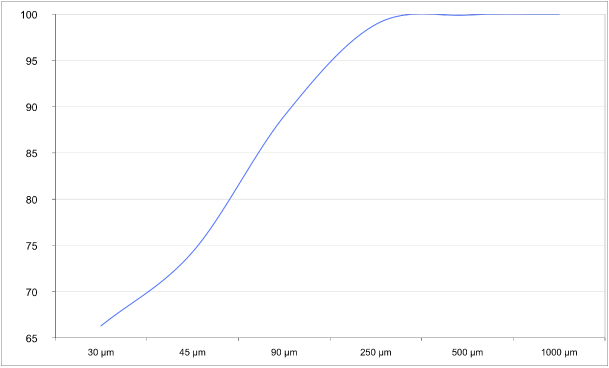

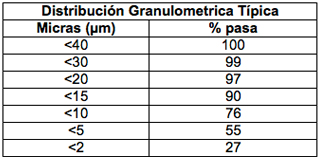

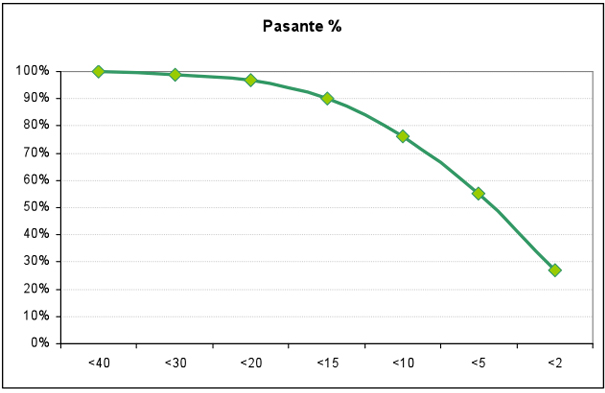

Within the range of lime-based products, the R&D&I department of Cementos Tudela Veguin has developed a new product called “MICRONIZED LIME”.

Micronized lime is a type of finely milled quicklime, with its maximum particle size in the micron range. This lime allows for a reactivity and solubility improvement as opposed to lime with conventional grain sizes (0-2 mm), making it ideal for its use in industries requiring a larger specific surface area or greater fluidity of the lime used.

USES

Micronized lime is used mainly in the siderurgical and metallurgical industry, in the treatment of acid waste, while also as a biocide in agriculture and in the treatment of sewage sludge.

BENEFITS

The fineness of micronized lime makes it have a greater fluidity and larger specific surface area, together with greater reactivity.

TECHNICAL DATA

The chemical values are the normal ones for siderurgical lime, the only difference being the size. The average chemical values, together with the grain size curve of micronized lime are as follows:

A family of cements with differentiated characteristics from those of common cements was born from the need to respond to the needs of clients in the field of special binders.

The objective consisted in achieving cements with an extremely high fineness and a specific grain-size distribution for their application in civil engineering and building constructions:

- Impregnation injections: previous and subsequent stabilisation in tunnels, mines,…

- Jet grouting applications: land consolidation, waterproofing of filtrations due to a rising water table.

- Injection in micro-fissures: rehabilitation of all types of work: bridges, dams, viaducts, singular and historical buildings,

DEVELOPMENT

The function of this product is to achieve a high penetration in land with low permeability, in such a way that the process is similar to granular matrix filtering. This improves the range of the injections and their durability, as a high stability cement matrix is created. Also, it is not degraded throughout time, as opposed to other types of chemical product injections, making it a recommendable solution from the environmental point of view.

Taking into account these premises from the start and always in permanent contact with our commercial team, the Production and Quality and R&D&I departments of the industrial branch of Corporación Masaveu commenced working in a joint manner to find the technical solutions leading to a product which could satisfy the following requirements:

- A fineness under 32 microns..

- Optimum dispersion in water. High fluidity..

- The achievement of stable and non-exuding grout..

- Great penetration in fissures and closed spaces..

- Optimum mechanical resistances..

- The possibility of being resistant to sulphides (upon request).

SUPPLY FORMATS

- Paper sack with a plastic film.

- Different capacity big bags.

- Gravity silos with mixer included at the base, refillable by means of tank trucks.

Grant grant from IDEPA

06/03/2023

IDEPA GRANT FOR THE PROJECT “DIGITAL TRANSFORMATION OF PLANT ENERGY MANAGEMENT”

The Economic Development Agency of the Principality of Asturias (IDEPA), as part of the Open Innovation call for the financial year 2022, has awarded a grant to Cementos Tudela Veguín, S.A. for the development of the project “Digital transformation of energy management system at plant”.

The project also receives public co-financing through the FEDER program of the European Union. The implementation of a system to automate data ingesting from the company’s production centers and external sources, as well as its storage and massive processing. The goal is also to perform an effective data exploitation and to obtain predictive models that may be of assistance to the company in order to optimize its energy consumption.

Grant grant from IDEPA

06/03/2023

IDEPA AID PROJECT TO INVESTIGATE AND DEFINE A THREE-DIMENSIONAL FORECASTING MODEL

The aim of the project is to investigate and define a new three-dimensional forecasting model through the use of the Finite Element Method (FEM), which will allow sustainable mining to continue at the El Perecil quarry and also extend its working lifespan.

CTV intends to acquire the new knowledge necessary in order to develope an efficient and optimized tool which will then be used to extend the extraction period of the above-mentioned quarry. The new tool will deliver real-time data concerning the water division at the saltwater/freshwater boundary of the hydrographic basin in the vicinity of the open-cast excavation whilst also providing a clear picture of the truly-exploitable reserves of the quarry.

Grant grant from IDEPA

06/03/2023

PROJECT RESEARCH AND DEFINE NEW CONDITIONING TREATMENTS FOR LANDFILL FLY

The project’s main aim is to research and define new conditioning and functionalization treatments for landfill fly ash for its posterior use in water decontamination as well as the formulation of enhanced-performance mortars.

CTV plans to synthesize zeolites and geopolymers for the removal of heavy metals from water; to establish fly ash functionalization techniques in order to recover cenospheres and to consequently elaborate a high-performance mortar in terms of thermal by means of the above-mentioned cenospheres. CTV will also determine rare earth elements present in fly ash in order to assess techniques for the recovery of these essential raw materials.

Grant grant from IDEPA

06/03/2023

FLOATING CONCRETE PROJECT

The primary aim of the FLOATING CONCRETE project is to establish new formulations of ultra-high performance concretes and mortars that can be directly employed in floating offshore wind energy production.

By doing so, CTV will contribute to the competitiveness of the Spanish offshore wind industry, enabling it to maintain a leading position in the sector and keep pace with the significant forecasted growth.

CTV intends to carry out the study, definition and design of new methods to determine and quantify non-conventional properties of concretes and mortars. Also, CTV will design high performance concretes with minimal environmental impact and will develop mortars that offer optimal performance for use in a marine environment.

Grant grant from IDEPA

01/07/2021

Feasibility study of a cement-based product manufactured using 3D printing techniques.

The Institute of Economic Development of the Principality of Asturias (IDEPA), within the call for Differential R + D + i Projects or Tractors for the year 2020 (RIS3-Company Program) and within the framework of the Science, Technology and Innovation Plan ( PCTI), has awarded a subsidy to Cementos Tudela Veguín. The project also receives public co-financing through the ERDF program of the European Union.

It consists of a feasibility study that will have as a general objective, and based on the existing technologies of 3D printing of construction materials, the analysis of their applicability to the different industries where construction work and processes are present, such as the residential construction sector, civil works and infrastructures, ornamentation or others that may benefit from advances in this field.

The project includes the conceptual development of two printable products in previously detected fields, also obtaining a prototype capable of showing the benefits of technology.

Grant grant from IDEPA

02/26/2019

MULTICAL: Industrial research on materials and multiple decontamination processes with products based on lime hydrate in a thermoelectric plant.

The Institute of Economic Development of the Principality of Asturias (IDEPA), within the call for Differential R + D + i Projects or Tractors for 2018 (RIS3-Company Program) and within the framework of the Science, Technology and Innovation Plan ( PCTI), has awarded a subsidy to the consortium formed by Cementos Tudela Veguín SA, Hunosa and AST Ingeniería. The project also receives public co-financing through the ERDF program of the European Union.

The research is aimed at developing an advanced material based on lime hydrate that, in the near future, will be used in the Hunosa thermoelectric plant with the aim of reducing its polluting emissions. For this, it will be necessary to adapt the industrial installation, modifying it based on an optimized design using fluid-dynamic simulation techniques.

Committed to the environment, the possible ways of valorization of the material flows out of the process will also be investigated.

IDEPA grant award

02/01/2018

Industrial research for the manufacture of thermally and electrically conductive materials with advanced cementitious and carbonaceous materials.

Within the call made by the Institute of Economic Development of the Principality of Asturias (IDEPA), within the framework of the Science, Technology and Innovation Plan (PCTI) 2013-2017, for the year 2017, a subsidy has been awarded to the consortium participated by Cementos Tudela Veguín SA and Industrial Química del Nalón, for a project to develop advanced mortars in terms of their thermal and electrical conduction properties. This project receives public co-financing through the ERDF program of the European Union.

In the search for new market niches and in the environment of energy efficiency and electrical protection, an opportunity for joint development has been identified by Cementos Tudela Veguín, S.A. and Industrial Química del Nalón, S.A. for the generation of a new mortar with highly improved conductive properties (thermal and electrical) with respectful environmental behavior and which, at the same time, can guarantee the durability of constructions.

The programming includes specific tests, with various materials and matrices from both industries, aimed at finding effective solutions to the current market demands that are increasingly specific and technified.

IDEPA grant award

02/01/2017

Improved efficiency and productivity in cement plants through an Industry 4.0 production model.

Within the call made by the Economic Development Institute of the Principality of Asturias (IDEPA), within the framework of the 2013-2017 Science, Technology and Innovation Plan (PCTI), for the 2016 financial year, a subsidy has been awarded to Cementos Tudela Veguín SA for a project focused on the implementation of the Industry 4.0 model in its cement plants. This project receives public co-financing through the ERDF program of the European Union.

The constant modernization of the facilities, incorporating more and more measurement and control systems, has been associated with the generation of a high volume of data in all areas of activity, for the maximum exploitation of which new data analysis tools are necessary. from conventional statistics to Artificial Intelligence.

The objective of the project is to gradually implement these techniques, focused on Industry 4.0, in order to improve energy efficiency and reduce the consumption of non-renewable raw materials.

For the development of the project, we have the collaboration of the Department of Statistics of the University of Oviedo whose specialists will work in collaboration with the company’s technicians in the achievement of the proposed objectives.

With the execution of this project it is intended to increase the quality and sustainability of the manufactured products, as well as their competitiveness in the markets.

BUILD3D-PRINT

Comprehensive production process for the construction industry based on additive manufacturing technologies.

This project has been co-financed by the European Regional Development Fund (ERDF), within the Operational Program for Smart Growth 2014-2020, with the aim of promoting research, technological development and innovation.

The objectives that have been set in this ambitious project are framed within additive manufacturing technology for construction. The main axes are the development of advanced materials for technology, construction engineering and the search for applications.

Cementos Tudela Veguín S.A, through this project, will develop new advanced materials and high added value for this technology that is progressively being implemented in all sectors of society.

Industria

Industria Bodegas

Bodegas Aparcamientos

Aparcamientos Inmobiliaria

Inmobiliaria Medicina

Medicina Internacional

Internacional Arte

Arte